Ochan Breakthrough in the technical bottleneck of biomass pellet machine

2016-06-04

[China News Network March 15 ] with the advent of world energy crisis of comprehensive and biomass fuel is gradually put on the agenda. And compared to conventional fuels, biofuel production is more simple, with green, environmental protection, energy saving, and other characteristics, biomass pellet machine is to produce bio fuel material of main equipment. The current global bio fuel consumption up to three countries sequentially for Germany, France and Spain, the application of domestic biofuel is gradually popularized. Recently there was more good news, Guangdong Austrian new energy science and Technology Co., Ltd. to break the bottleneck of biomass pellet machine technology, domestic development of biomass energy reproduction tremendous business opportunities.

Domestic biomass pellet machine manufacturers in the high cost of a sore point uneven in quality.

Until the end of 2015, the domestic biomass pellet machine manufacturer has more than 500, but its current situation is not optimistic. At present domestic biomass pellet machine manufacturer level not neat, equipment production line technological backwardness, high energy consumption, low productivity, complex operation, failure rate high resulting in high production costs, wasted a lot of cost and energy, eventually leading to biofuel producers to profitability, manufacturers were forced to close or a career change.

OCHAN breakthrough technology bottlenecks, low cost, high return industry Savior.

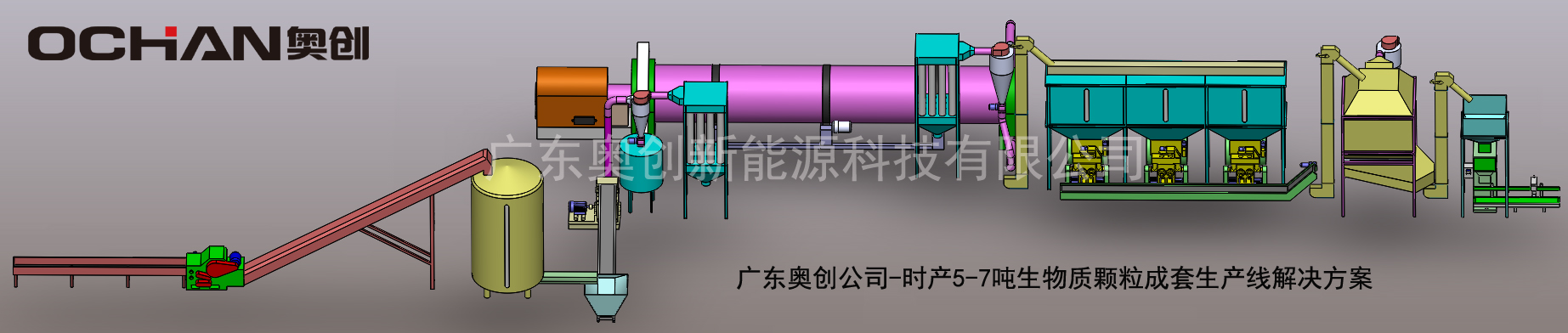

Guangdong Ochan new energy Technology Co., Ltd. was established in 2010, from the initially unknown biomass to produce fuel factory now new national energy leading persons, the Olympic record personally experienced the change and development of the industry. Olympic record constantly absorbing foreign advanced production technology, the introduction of the industry's top people only, after all the hardships, culminating in the production of R & D out with independent intellectual property rights of the biomass fuel production line sets. This production line capacity is high, low energy consumption, simple operation, convenient maintenance, all-weather 24 hours of uninterrupted and stable operation.

Olympic record R & D department manager Chen said that compared with traditional equipment production line, the Olympic record production of electricity cost of a ton of granular host directly from 100 yuan fell to around 45 yuan, production costs straight down more than 2 times. If a particle of each plant monthly production index of 1000 tons, then comprehensive annual increase benefits will exceed 70 million yuan, truly energy-saving value-added.

One-stop comprehensive solutions run through the entire production chain, effectively operating efficiency is obvious.

In addition to providing high-tech biomass pellet machine equipment for the domestic producers, the Olympic record for the user to provide production technology, a full set of production line solution. From raw materials to collect fuel production, from the whole plant planning to fuel sales, energy management, the Olympic record to achieve the whole industry chain one-stop integrated service purpose. The whole operation process can be for users to save more than 20% of the cost of investment, business benefits are obvious, by the majority of users.

Preparation of bio energy fuel, easy and efficient, clean, renewable, energy conservation and emission reduction, to achieve the better economic and social benefits. The Olympic record new biomass fuel production line to add to the biomass energy weapon, I believe that in the near future, bio energy will become a universal fuel, biomass pellet machine attendant will also become hot meat and potatoes, the future of biomass energy can be described as unlimited business opportunities.

Online Mall

Online Mall