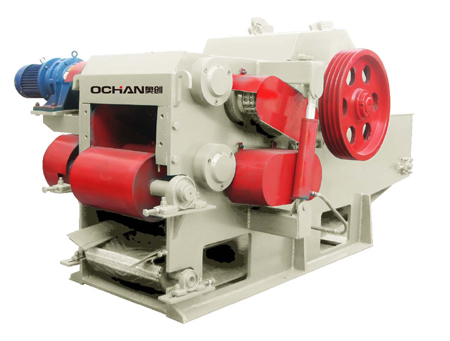

OCGS drum-type chip crusher

2016-06-01

Product brief introduction

Drum-type chip crusher series of products which is not need to built a foundation,it’s the special equipment for the production of wood biomass material.The product is widely used in particleboard plant, moderate and high density fiberboard factory, biomass power plant, wood factory, and other industrial and manufacturer,it is the preferred equipment in the preparation of the material section. The product has advanced structure, high cutting quality, wide raw material adaptability, convenient operation and maintenance.

Application range

The cutting main raw material for small-diameter wood, timber harvesting ,processing residues (such as branches, branches, and slab, slab laser, core, log, waste veneer), The crusher is also used for cutting non wood raw materials (such as sugar cane, reed, bamboo, etc).

Product feature

(1)The body of machine is welded with high strength alloy steel plate,the whole machine is firm and durable;

(2)According to the customer demand for raw materials we can customize the machine which can be installed two to six fly-cutters.We use specially made fly-cutter bolts, through the pressure block, the fly-cutter is fixed on the knife roller;

(3)According to the cutting raw materials with different thickness ,when the raw material into the internal machinery, the feeding roller will float down in a certain range with the help of the hydraulic system.

(4)Cutting down the qualified sheet of material through the sieve hole, exhausted from the bottom sheet,large slice of material will be cut in the machine until it is qualified;

(5)Hydraulic system and auxiliary system, by the oil pump to supply oil cylinder, easy blade replacement; easy to lift the feed roller ,easy to adjust the clearance of fly-cutter and to remove or install comb plate.

Product parameter

Model | OCGS215 | OCGS216 | OCGS218 | OCGS2110 | OCGS2113 | OCGS6213 |

Knife-cylinder diameter(mm) | 500 | 650 | 800 | 1000 | 1300 | 1300 |

Fly-cutter number(PCS) | 2/3/4 | 2/3/4 | 2/3/4/5 | 3/4/6/8 | 3/4/6/8 | 3/4/6/8 |

Feed inlet size(mm) | 180*400 | 240*540 | 310*680 | 500*1000 | 400*700 | 550*1480 |

Feed rate(m/min) | 38 | 38 | 38 | 38 | 38 | 35 |

Max.Feed size(mm) | 160 | 230 | 300 | 420 | 380 | 380 |

Cutting length(mm) | 15-35 | 15-35 | 15-35 | 25-35 | 25-35 | 30-50 |

Feed roller power(wk) | 2.2*2 | 3*14*1 | 4*2 | 11*2 | 7.5*2 | 11*118.5*1 |

Main motor power(kw) | 45 | 55 | 110 | 132 | 200 | 315 |

Dimension(mm) | 1540*1240*1020 | 1980*1950*1250 | 2300*2150*1500 | 3850*2450*2050 | 3670*2450*2050 | 3670*3300*2050 |

Revolving speed(Rpm) | 590 | 590 | 650 | 500 | 500 | 426 |

Weight(t) | 2.9 | 4.1 | 7 | 12.5 | 13 | 18 |

Product capacity(t/h) | 5-8 | 8-12 | 10-20 | 15-25 | 20-35 | 35-50 |

Remark:We can customize the mobile crusher for you. | ||||||

Online Mall

Online Mall